How is 3D printing revolutionizing medical prosthetics?

The intersection of technology and healthcare has always led to significant advancements in patient care. This synergy has never been more evident than in the development of 3D printed prosthetics. This innovative approach to medical device manufacturing is revolutionizing the healthcare industry, offering possibilities that could only have been dreamed of a few short years ago.

The Role of 3D Printing in Medical Prosthetics

First, let’s delve deeper into understanding how 3D printing is impacting the world of medical prosthetics. This technology, also known as additive manufacturing, constructs three-dimensional solid objects from a digital file. It involves the layering of materials until the desired object or part is created.

Sujet a lire : What are the applications of AI in rare disease research?

Traditionally, the production of prosthetics is a lengthy, expensive, and complex process that often results in less-than-ideal outcomes for patients. With the advent of 3D printing, it is now possible to create prosthetics that are customized to each patient’s specific needs, ensuring a better fit and enhanced functionality.

The Advantages of 3D Printed Prosthetics

There are numerous advantages to employing 3D printing technology in the manufacture of prosthetic devices. Perhaps most critically, it provides a significant reduction in cost. Traditional prosthetics manufacturing can cost thousands, even tens of thousands, of dollars per device. 3D printed prosthetics, on the other hand, can be produced for a fraction of that cost. This makes such devices more accessible to a broader range of patients, particularly in low-income regions or countries.

A découvrir également : How can quantum computers advance materials science?

In addition to cost savings, 3D printed prosthetics offer a quicker turnaround time. Traditional prosthetics can take weeks or even months to manufacture, while a 3D printed version can be completed in a matter of days or hours.

Furthermore, 3D printing enables the creation of prosthetics that are highly customized to the individual patient. Traditional manufacturing methods often result in ‘one-size-fits-all’ devices, which may not fit the patient perfectly or meet their specific needs. In contrast, 3D printed prosthetics can be tailored to the patient’s exact anatomical requirements, offering a better fit and improved functionality.

The Impact of 3D Printing on Surgical Applications

The benefits of 3D printing in the healthcare industry extend beyond prosthetics. One of the most promising applications is in the realm of surgery. Surgeons can utilize 3D printed models to plan and practice surgical procedures, reducing the risk of complications and improving patient outcomes.

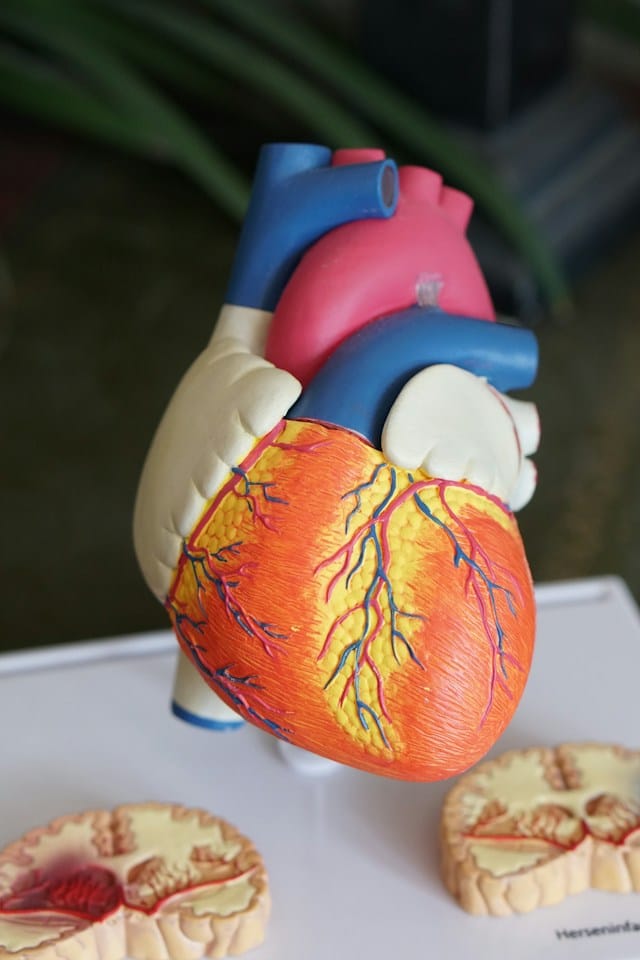

For example, a surgeon can use a 3D printed model of a patient’s heart, brain, or other body parts to visualize and understand the patient’s specific anatomy. This helps the surgeon to plan their approach and anticipate potential challenges before stepping into the operating room.

Moreover, the use of 3D printing in surgical applications extends to the creation of implants. Custom-fitted 3D printed implants can be produced, which are more comfortable and functional for patients when compared to mass-produced implants.

Future of 3D Printing in the Medical Industry

While the impact of 3D printing in the medical industry is already profound, the future holds even more promise. With continual advancements in technology and materials, the possibilities are virtually endless.

One exciting area of research is in the field of bioprinting, where scientists are working to manufacture functional organs using 3D printing technology. While this is still in the experimental stages, the potential implications are staggering. Imagine a future where patients in need of an organ transplant could have one printed for them, using their own cells to minimize the risk of rejection.

Furthermore, the development of new materials for 3D printing continues to expand the possibilities for medical applications. Materials that can mimic human tissue or bone are being developed and refined, paving the way for even more detailed and functional prosthetics and implants.

As you can see, 3D printing is truly revolutionizing the field of medical prosthetics, and its impact on the healthcare industry at large is only set to grow. As technology continues to evolve, so too does the potential for improved patient care and outcomes. In the hands of dedicated medical professionals and inventive engineers, the future of healthcare looks bright indeed.

Real-Life Cases: 3D Printing in Action

In recent years, we’ve witnessed a growing number of real-life cases where 3D printing technology has made a profound impact in the medical field. From creating patient-specific prosthetic limbs to crafting anatomical models for surgical planning, the use of 3D printing in healthcare is already making waves.

One notable example is the case of a young boy from Sudan who lost his arms in a bomb blast. With the help of a 3D printer, a team of engineers was able to construct a low-cost, functional prosthetic arm for the boy. This would not have been possible with traditional manufacturing methods due to the prohibitive costs and lack of infrastructure in the war-torn region.

Another compelling case comes from the field of dentistry. A patient in need of a complex dental implant received a 3D printed version that was tailored to her unique jaw structure. This not only resulted in a more comfortable fit but also significantly reduced the amount of time she spent in the dentist’s chair.

In the realm of surgical planning, 3D printed models have been used to assist surgeons in achieving successful outcomes in complex procedures. For instance, a selective laser sintering (SLS) 3D printer was used to create a detailed model of a patient’s skull before a challenging neurosurgery procedure. This allowed the medical team to practice the operation beforehand, significantly reducing the risk of complications during the actual surgery.

These examples show that 3D printing isn’t just a theoretical concept or a future innovation – it’s a technology that’s already changing lives in the present.

Conclusion: Transforming Healthcare Through 3D Printing

The impact of 3D printing on the medical industry is undeniable. Whether in the creation of cost-effective, patient-specific prosthetics, or in the precision of surgical planning using anatomical models, this technology is revolutionizing healthcare in ways we could only imagine a decade ago.

The power of 3D printing lies in its ability to create complex, customized medical devices in a faster and more affordable manner than traditional manufacturing methods. It’s a technology that empowers medical professionals to provide better, more personalized care for their patients.

Looking ahead, the possibilities are endless. With the advent of bioprinting, we may one day be able to print functional organs for transplant. The continued development of new materials could lead to even more realistic and functional printed prosthetics and implants.

The future of 3D printing in medicine is bright and full of potential. As we continue to explore the capabilities of this groundbreaking technology, we can look forward to even more transformative changes in the medical field. From patient-specific devices to printed models for surgical planning, 3D printing is truly reshaping the landscape of healthcare.